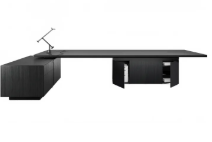

tölvuborð verksmiðja

Vélborðsaðgerð er nútímaleg framleiðsluaðstaða sem er einbeitt að framleiðslu ergónomískra og virka vinnustöðva fyrir fjölbreyttar tölvuþarfir. Í stofnuninni eru búnir að vera samhliða háþróaðri sjálfvirkni og nákvæmni til að búa til endingargóðar og sérsniðin tölvuborð. Nýjustu framleiðsluleiðir nota tölvuaðstoðna hönnun (CAD) og tölvuaðstoðna framleiðslu (CAM) tækni til að tryggja stöðuga gæði og nákvæmni á stærðum. Vinnustöðin hefur fjölda gæðaeftirlitsstöðva í framleiðsluferlinu, frá hráefnaeftirliti til lokavörunar. Með háþróaðum klippinga- og samsetningarbúnaði getur verksmiðjan unnið með ýmis efni, þar á meðal verklegt tré, málm og samsett efni. Á framleiðsluhæðinni eru sérsviðs svæði fyrir mismunandi framleiðsluáfanga: klippa, kantband, samsetningu, gæðaeftirlit og umbúðir. Umhverfisáherslur eru samþættar í framleiðsluferlinu með ryksöfnun og endurvinnslu úrgangs. Rannsóknar- og þróunardeild stofnunarinnar vinnur stöðugt að nýstárlegum hönnunartækjum sem taka tillit til þróunarkrafa á vinnustaðnum og ergónomískra staðla. Vinnustofan hefur sveigjanlegt framleiðsluáætlun til að koma til móts við bæði stórar pöntunar og sérsniðin beiðni, studd af skilvirku birgðarstjórnunarkerfi sem tryggir hagstætt efniflæði og styttan framkvæmdatíma.